Why Flat Rolled Products Will Define the Next Decade of the North American Aluminum Industry

The North American aluminum industry is at a crossroads. Demand for flat rolled products (FRP) is set to nearly double by 2035¹, despite already facing a shortfall of more than 2 million tonnes annually. Growth in electric vehicles, beverage packaging, aerospace, and construction is accelerating the need for reliable supply, but production capacity is struggling to keep up the pace.

For manufacturers, the implications are significant. Limited access to FRP means higher costs, delayed innovation, and greater reliance on imports. With tariffs restricting imports and energy prices challenging domestic smelting, now’s the time for the industry to prioritize more efficient, sustainable, domestic source and resilient production methods.

In this article, we’ll look at what’s driving the FRP supply gap, why it matters for industries across North America, and how Golden Aluminum’s Nexcast® system is positioned to meet rising demand with efficient, sustainable production.

How the FRP Deficit Affects Key Industries

The FRP deficit poses major consequences for North America’s biggest industries. From consumer goods to advanced manufacturing, every sector will feel the strain.

- Automotive: As EVs become more common, an aluminum shortage could mean higher material costs and production slowdowns.

- Beverage packaging: Cans are among the most recycled products worldwide, yet supply constraints risk pushing brands toward less sustainable alternatives.

- Aerospace: Aircraft manufacturing requires advanced aluminum alloys with strict performance standards. Any disruption in access poses both economic and operational risks.

- Construction: Aluminum’s strength and recyclability make it vital to infrastructure and housing projects. With investment in construction on the rise, expanding domestic FRP capacity will help ensure steady progress and long-term growth across the sector.

These challenges highlight why expanding domestic FRP production is essential—not only to meet future demand, but also to ensure the resilience of North America’s key industries.

Market Growth and Rising Demand

The North American FRP market, valued at approximately USD 8.5 billion in 2024, is expected to nearly double to USD 17.1 billion by 2035. Globally, aluminum demand is predicted to grow by nearly 40% by 2030, adding over 33 million tonnes of new consumption², ⁶.

One of the major drivers is the shift toward lighter, more efficient vehicles. In 1980, the average white-goods or passenger vehicle might have used around 120 pounds of aluminum; by 2030, that number could rise toward 556 pounds per vehicle as automakers adopt more aluminum in EV bodies and components. That increase alone represents millions of tonnes more aluminum demand globally.

Meanwhile, US and Canadian production capacity–especially for flat rolled products in key alloys–is constrained. Scaling up will require investment, both in raw capacity and more efficient, agile production techniques.

What’s Driving the Supply Gap?

Several factors explain why supply is struggling to keep pace with demand:

- Trade Policy and Tariffs: In June 2025, Section 232 tariffs on imported aluminum doubled to 50% (excluding the UK)⁴, ⁵. These protections reduce access to foreign supply while increasing costs.

- Pandemic Disruptions: COVID-19 exposed weaknesses in global supply chains, from raw material sourcing to shipping logistics. Many of those challenges are still felt today.

- Energy Costs: Aluminum smelting is energy-intensive. In the US, high electricity prices make restarting or expanding smelters difficult, especially as competition for power grows with technology and data center demand.

The result is a structural imbalance: strong and growing demand with limited–and often unreliable–supply.

Why this Matters for Industry Leaders

A heavy reliance on imports leaves manufacturers exposed to tariff uncertainties, unpredictable shipping timelines, and geopolitical risks. The FRP deficit sends a clear signal: now is the time to expand domestic production capacity. Companies that invest early in sustainable, efficient technology will be best positioned to meet future demand while providing stability to customers and industries.

The Nexcast® Advantage at Golden Aluminum

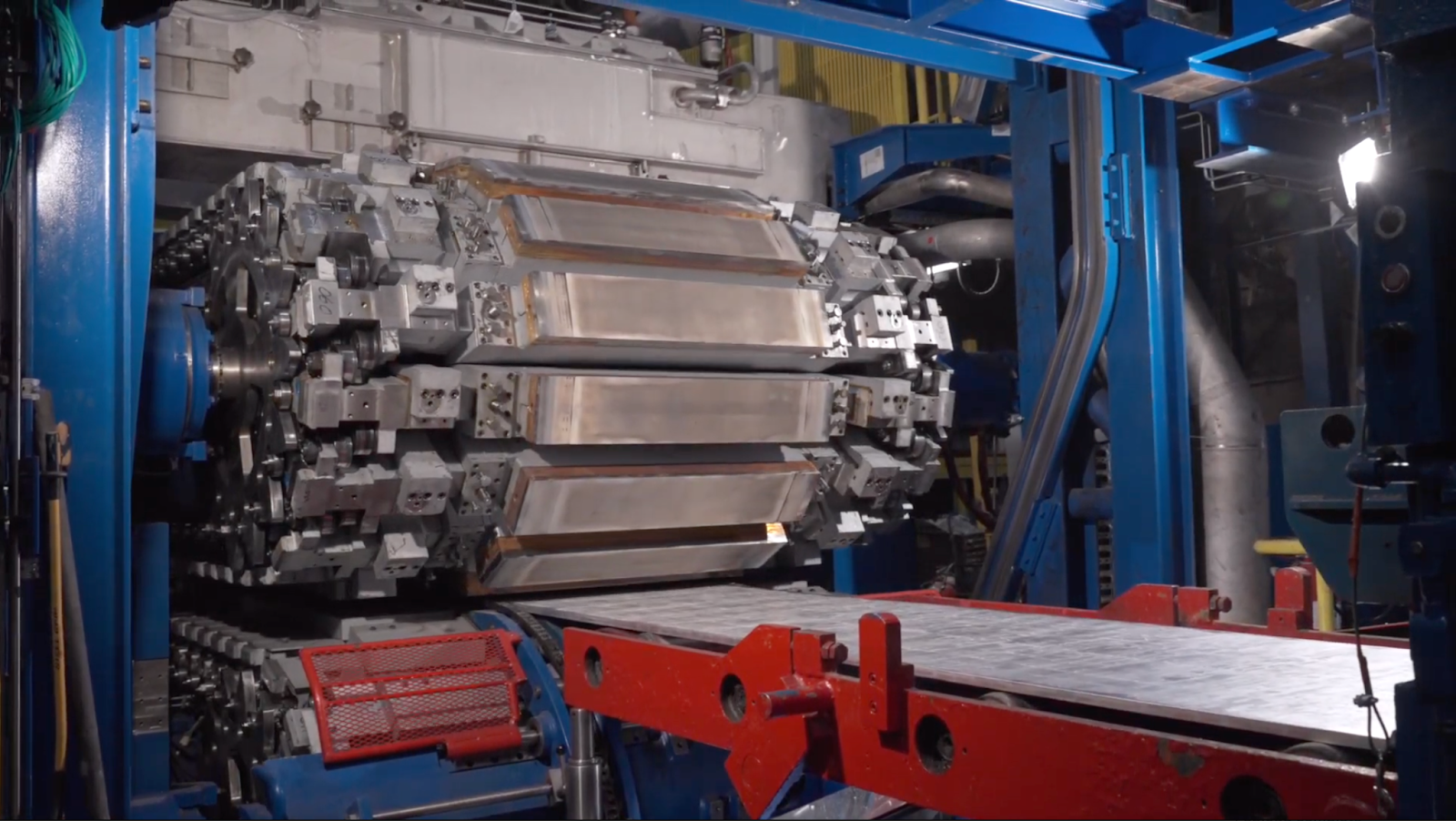

Since 1982, we at Golden Aluminum have built our business on innovation and agility. This spirit of innovation led to the development of our Nexcast® continuous caster technology: a key player in shaping a smarter, faster, and more sustainable future for aluminum manufacturing.

Built on decades of proven, continuous casting expertise at Golden Aluminum, our Nexcast ® technology is engineered for versatility and high-performance manufacturing—and is well positioned to respond to this moment of rapid demand growth.

Unlike traditional processes, Nexcast® delivers:

- Diverse Alloy Capability: Nexcast® technology supports production of a wide variety of alloys.

- Energy Efficiency: The system uses less energy per tonne of output compared to traditional DC processes, aligning with industry goals for lower-carbon aluminum.

- Flexibility and Agility: Nexcast® allows for on-the-fly alloy changes and rapid response to customer needs, ensuring shorter lead times and reliable supply.

- Domestic Reliability: The first Nexcast® has been installed in our Fort Lupton, Colorado, Golden Aluminum mill—offering a secure, US-based supply chain that reduces reliance on imports.

Nexcast® technology isn’t just keeping pace with market demand. It’s helping set the standard for the future of flat rolled products.

Looking Ahead

The North American FRP deficit represents both a risk and an opportunity. For industries that rely on aluminum, the risk lies in constrained supply chains. For producers, the opportunity lies in meeting surging demand with efficient, sustainable, and domestic production.

Golden Aluminum is prepared for this future. Through our Nexcast® technology and commitment to efficiency, sustainability, and reliable domestic supply, we’re helping to close the supply gap while supporting growth in automotive, packaging, aerospace, and construction markets.

If you’re looking to understand more about how Nexcast® works, or explore how Golden Aluminum can be your partner in reliable FRP supply, we’d love to connect. Explore our website or reach out to our team today.

Sources

- https://www.marketresearchfuture.com/reports/north-america-aluminum-flat-rolled-products-market-47426

- https://www.weforum.org/stories/2023/11/aluminium-demand-how-to-make-it-sustainable/

- https://www.aluminum.org/auto-aluminum-growth-era-electrification

- https://www.whitehouse.gov/fact-sheets/2025/06/fact-sheet-president-donald-j-trump-increases-section-232-tariffs-on-steel-and-aluminum/

- https://www.whitecase.com/insight-alert/trump-administration-increases-steel-and-aluminum-section-232-tariffs-50-and-narrows

- https://international-aluminium.org/report-reveals-global-aluminium-demand-to-reach-new-highs-after-covid/

Team Golden Aluminum

Share

Related Posts

New Year, New Plan: Choosing the Right Aluminum Partner for 2026

January 13, 2026

How Aluminum Makes the Holiday Season Bright

December 5, 2025

Golden Aluminum Celebrates Manufacturing Day 2025

October 22, 2025