A Leap Towards a Brighter Future: DOE Grant and Our Master Plan

DOE Grant and Our Master Plan

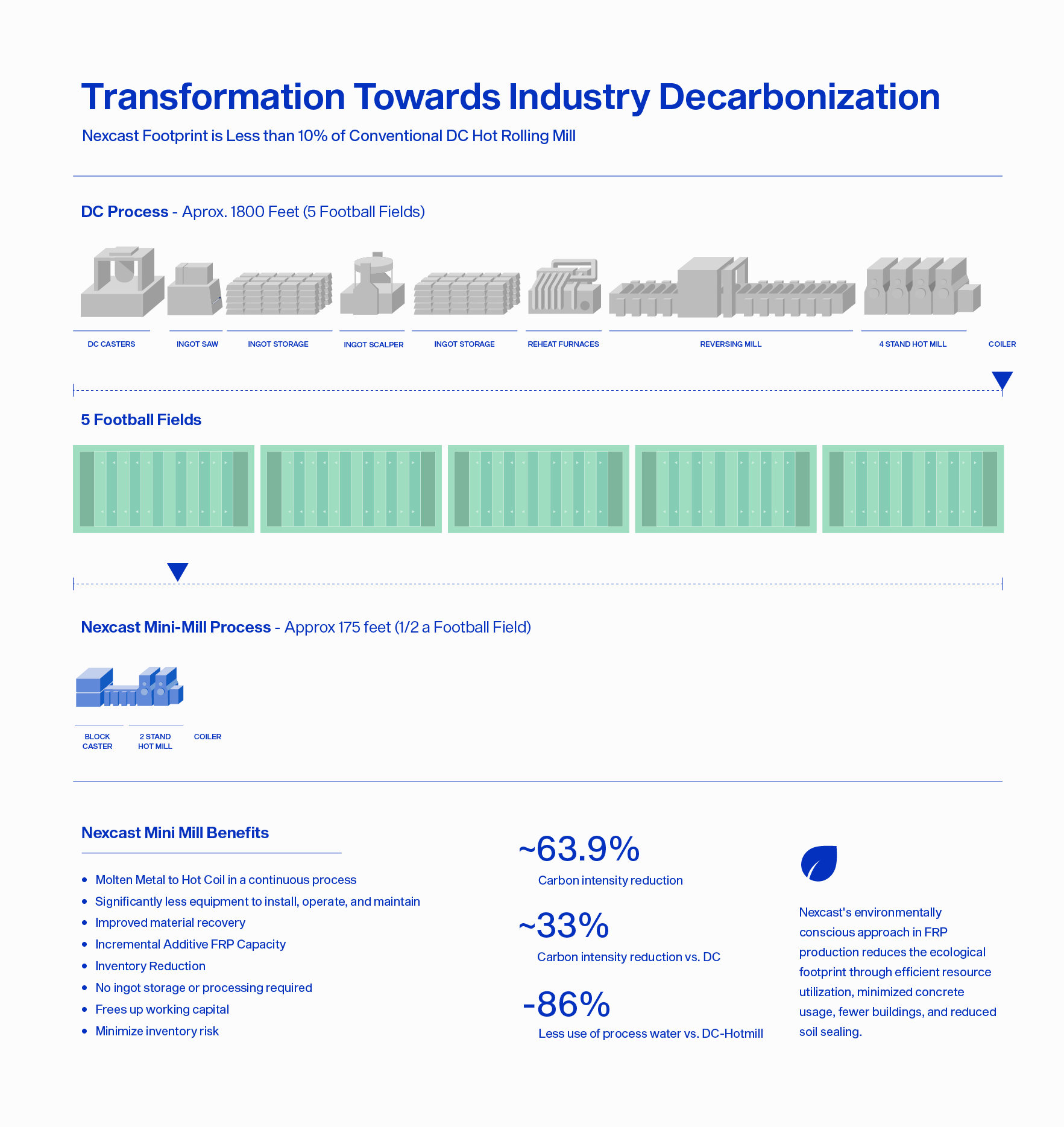

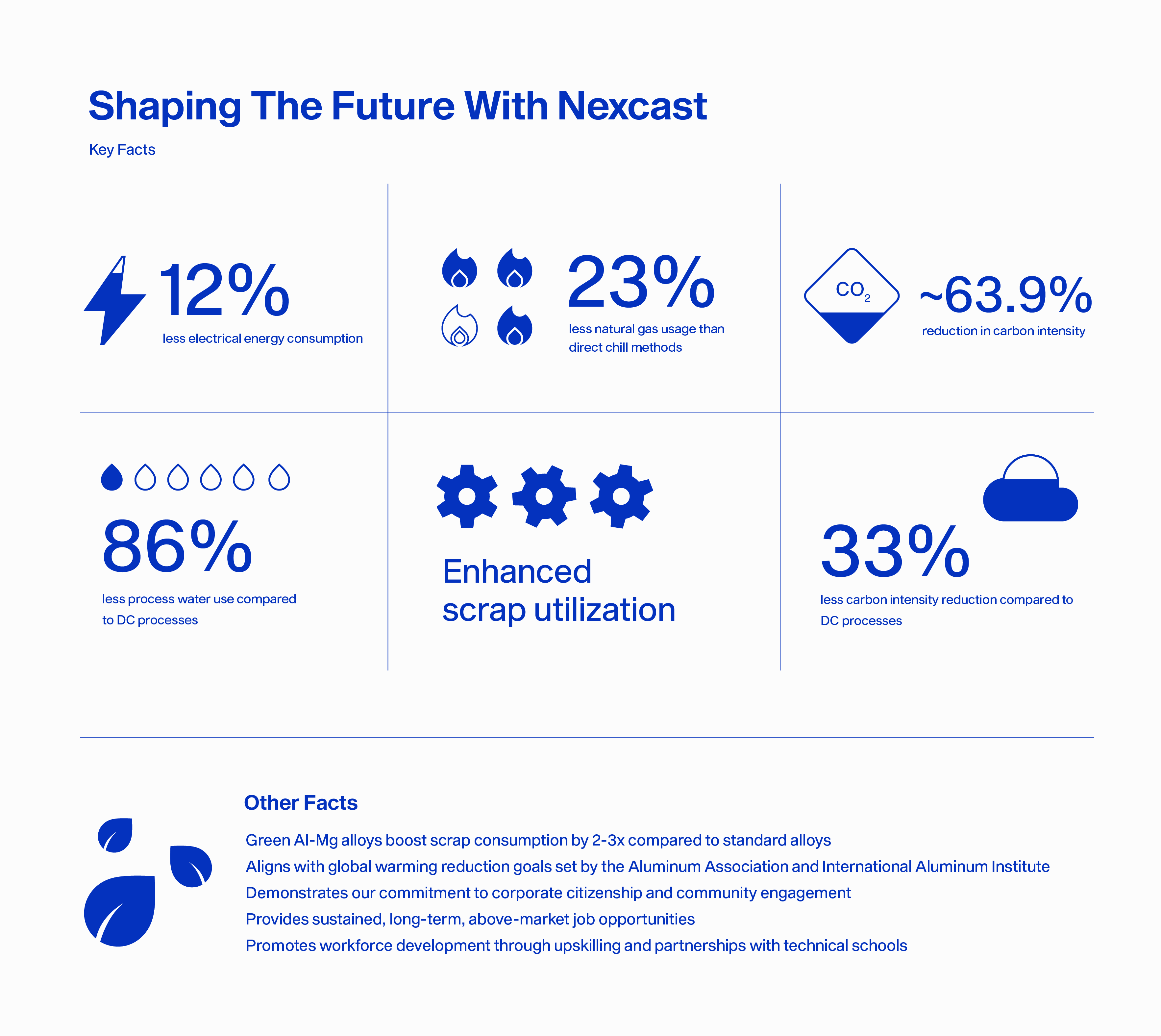

At Golden Aluminum, we’re serious about making a positive difference on our planet. Our continuous cast technology, Nexcast, sets a new standard in sustainability for the entire industry.

Exciting news has sped up our efforts. The Department of Energy has selected us to begin negotiations to receive up to $22.3 million in investments. We feel honored and proud of this recognition, and thankful to our new partner.

However, our vision goes much farther.

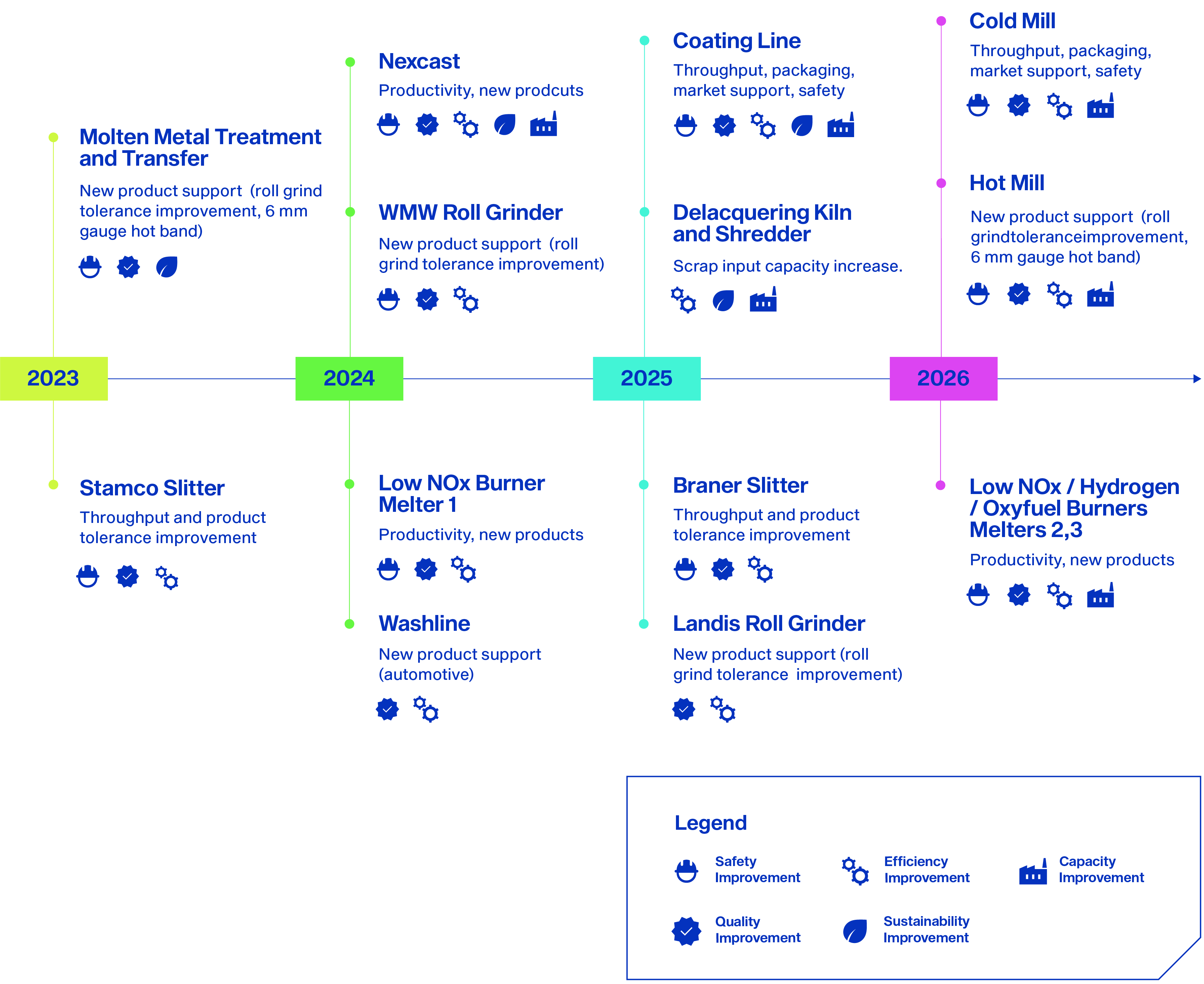

Looking to the future, we’ve laid out a master plan, solidifying our commitment with an incremental investment of approximately $60 million over the next five years to make our vision a reality.

But what does this mean for the industry, our clients, and the GAI family?

Our master plan will support our growth strategy, increasing operational efficiency with higher quality and safety standards. Strengthening our role and leadership in continuous cast technology for aluminum sheet and producing alloys with industry leading recycled content.

- Advancing Nexcast technology offers a greener and more efficient alternative for manufacturing secondary flat-rolled aluminum sheet.

- Upgrading our delacquering kiln and shredding capabilities will broaden the spectrum of scrap sources we can process, improving our ability to increase the recycled content in our products.

- Introducing state-of-the-art low NOx burners offers multiple benefits, including improved air quality, energy efficiency, future regulatory compliance, and enhanced equipment performance, making them a key investment.

These investments will modernize our plant, improving both productivity and safety, and expand our capacity to 70 million pounds by 2028 while improving product quality.

How does Nexcast shape the industry’s future?

Sustainability and Social Responsibility

Nexcast technology is essential in advancing decarbonization within the aluminum industry. It sets a new standard in recycling efficiency, significantly reducing carbon emissions, water and energy consumption that outperform traditional DC mills.

Nexcast is the most versatile aluminum continuous casting technology available on the market today with the ability to produce most alloys and flat rolled products.

The Facts:

To our dedicated team and valued customers, we appreciate your trust and partnership. You are the foundation of our success. As we enter this thrilling chapter of our history your ongoing support fuels our mission. We are creating a legacy of excellence and sustainability that will last. Thank you for being a crucial part of our journey towards a brighter, more responsible future.

We sincerely express our gratitude to the DOE for their partnership on this path, demonstrating solid backing for our efforts to promote decarbonization within the aluminum industry.

The Journey of Aluminum: From Bauxite to Your Front Door

I. Introduction

In every corner of our modern lives, aluminum asserts itself—be it in the vehicles we drive or the protective kitchen foils we use. While its presence is undeniable, few recognize the intricate journey that transforms this raw mineral into a cornerstone of contemporary living.

Aluminum’s tale begins with bauxite, a rugged mineral far removed from the refined gleam we’re accustomed to. But this transformation from earthy mineral to ubiquitous metal isn’t just about industrial processes—it’s a testament to the meticulous craftsmanship of its producers. Together, we shall journey through a story that marries precision with innovation, reflecting the heart of the aluminum industry.

II. Bauxite Mining: The Beginning of Aluminum’s Journey

Unbeknownst to many, bauxite mining is the starting line for aluminum’s journey. This reddish-brown mineral, found predominantly in tropical terrains, is a foundational element of the aluminum industry.

Bauxite mining is a meticulous process. First, layers of earth and vegetation are removed to reveal the bauxite, typically 4-6 meters below the surface. The bauxite is then excavated using earth-moving equipment and transported to refineries for processing.

However, the task isn’t merely about extraction. The finest suppliers uphold rigorous standards, selecting only superior bauxite to ensure a superior end product. Hand-in-hand with these standards is a profound commitment to the environment. Embracing sustainable mining practices is paramount. It’s not about depleting the earth but borrowing from it, ensuring minimal disruption to the ecosystem and surrounding communities.

III. Refining: Turning Bauxite into Alumina

The process of refining bauxite into alumina is an intricate, scientific process. Imagine taking a substance like bauxite, earthy and raw, and turning it into a pristine white powder called alumina, ready to be transformed further into aluminum.

This metamorphosis is achieved through the Bayer Process. Bauxite is first crushed and then mixed with a hot caustic soda solution, which dissolves the aluminum oxide contained in the bauxite. Once dissolved, impurities settle to the bottom, and the remaining alumina solution is allowed to cool. Alumina crystals form, are filtered, and then undergo a heating process to remove any leftover water.

Throughout this stage, precision is paramount. The goal? Ensure every grain of alumina achieves the highest purity. This meticulous attention to detail lays the foundation for what’s next: the magical conversion of this white powder into gleaming aluminum.

IV. Smelting: Birth of Pure Aluminum

Smelting is where alumina transitions from a dormant state to animated brilliance. Picture a mineral, in powder form, undergoing a sophisticated, energy-intensive procedure to emerge as a gleaming metal.

Central to this alchemical process is the Hall-Héroult method. Here, alumina undergoes electrolysis in molten cryolite, a naturally occurring mineral used to lower the melting point of alumina for the extraction process. A direct current is passed through the solution, causing the aluminum ion to deposit at the bottom of the reduction cell, where it can be tapped off.

However, the high energy demand of the process necessitates a conscious push towards more sustainable practices. It’s a challenge the industry takes in stride, always seeking innovations to balance purity with eco-responsibility.

V. Rolling and Casting: Crafting the Aluminum Sheet

Post-smelting, aluminum, in its newly acquired pure form, is ready for its next transformative phase. This is where the metal’s flexibility truly shines, being molded into sheets with specific properties tailored to their future applications.

The processes of rolling and casting are akin to the artistry of a blacksmith shaping a blade. Rolling involves passing the aluminum between high-pressure rollers to achieve the desired thickness. Meanwhile, casting solidifies molten aluminum into specific shapes using molds.

Every rolled or cast sheet is engineered for a distinct purpose. Whether it’s for the aerospace industry, can-making, aerospace, building products or everyday kitchenware, each sheet is a blend of science and craftsmanship. Manufacturers, with their acute knowledge, ensure that each sheet is not just tailored, but sculpted to perfection.

VI. From Manufacturers to End-Products

Behind every everyday object made of aluminum is an intricate process and a story of meticulous engineering. This lustrous metal, shaped and perfected, is destined for myriad applications, each one demanding a unique touch.

Consider the soda can you might sip from during lunch, or the sleek laptop casing you work on. These products, seemingly simple, are the result of rigorous design and manufacturing processes. The aluminum used in them has been selectively crafted to meet specific standards such as strength, flexibility, formability and appearance.

In this vast manufacturing dance, suppliers and manufacturers harmoniously collaborate. Their collective goal is to ensure every sheet of aluminum employed not only fits its intended role but exceeds quality expectations. This union between supplier and manufacturer is a testament to the industry’s dedication to superior product creation.

VII. Sustainability: The Golden Standard

In the vast tapestry of the aluminum industry, Golden Aluminum stands not just as a beacon of production, but as a pioneer championing sustainability’s transformative power.

A closer look at our operations illuminates this commitment:

- Bauxite Mining: Golden Aluminum block caster, utilizes recycled aluminum in percentages that are beyond the industry standards. This isn’t just an operational decision—it’s a testament to our forward-thinking commitment, lessening the environmental impact.

- Energy-Efficient Production: Drawing from the intricate processes unveiled in prior sections, our embrace of NexcastTM technology emerges as a paradigm of innovation. By radically reducing greenhouse gas emissions, and operating at higher energy-efficiency rates compared to other Mills. This isn’t just about operational excellence—it’s about redefining the balance between efficiency and our ecological footprint.

- Industry Recognition: Beyond our internal strides, our initiatives have garnered the attention of industry peers. Our esteemed affiliation with the Aluminum Stewardship Initiative (ASI) is both a validation and a testament to our unwavering commitment to sustainable operations.

In essence, sustainability at Golden Aluminum is not just an afterthought. It’s a core philosophy, part of our DNA, woven seamlessly into our operational fabric.

VIII. In Retrospect: Aluminum’s Promise for Tomorrow

The transformative tale of aluminum offers more than a mere insight into its creation; it mirrors our society’s ever-evolving aspirations and innovations. With every step of its journey, aluminum challenges us to view the commonplace with newfound appreciation and to recognize the profound in the ostensibly simple.

Golden Aluminum stands at this intersection of past achievements and future aspirations. By understanding and honoring the intricate processes of aluminum production, we acknowledge the responsibility we bear not just to our customers, but to the planet that provides for us.

Sustainable Aluminum Manufacturing: Why the Urgent Need for It?

In our dynamic global economy, the strategic importance of aluminum simply cannot be overstated. It is, in essence, one of nature’s most versatile metals, serving as the foundation for a wide range of industries, from food and beverage packaging containers, construction materials, automotive applications, and electrical components.

To fully comprehend the extent of this vast business, it is critical to grasp the key roles played by two primary actors: aluminum manufacturers and aluminum suppliers. Working in harmony, they meticulously convert raw materials into practical, ready-to-use products and subsequently facilitate their distribution across multiple sectors.

In this article, we aim to shed light on the complexity and importance of the aluminum industry. Specifically, we’ll delve into the process of aluminum production, the sustainability challenges it faces, and how forward-thinking companies are responding to these issues.

Join us on an enlightening journey as we unveil the fascinating secrets of the aluminum industry, a world integral to our daily lives.

Navigate to Any Section with Ease:

- Understanding Aluminum: From Extraction to Final Product

- The Importance and Implementation of Sustainability in Modern Aluminum Manufacturing

- Role and Responsibility of Aluminum Manufacturers and Suppliers

- Case Study: Golden Aluminum – A Beacon in Sustainable Practices

- Conclusion

Understanding Aluminum: From Extraction to Final Product

Aluminum’s journey, from its extraction from the earth to its transformation into a practical product, is a fascinating process. It begins with mining for bauxite, a sedimentary rock that is rich in aluminum and is the third most abundant element on Earth’s surface. This is a task that requires land clearing, digging, and blasting through thick sections of bauxite ore.

Once extracted, the bauxite is transported to a plant where it undergoes a refining process. Here, the rock is exposed to caustic soda under extreme temperatures, a technique designed to separate alumina from bauxite. The end product of this refining process is a delicate white powder known as alumina. It is fascinating to note that for every two pounds of alumina, one pound of aluminum can be created.

But the journey doesn’t stop there. The alumina undergoes a further process of smelting to yield pure aluminum. This involves melting and heating the alumina to temperatures of just over 700°C. The molten aluminum is then cast into various forms: ingots, large blocks, t-bars, or cylindrical logs called extrusion billets – yielding a product that is 99.8% pure.

The versatile nature of aluminum becomes evident in the next stage. The pure aluminum can be further refined to produce ultra-pure aluminum or alloyed with other metals to achieve different characteristics. Golden Aluminum, for example, melts ingots of pure aluminum with recycled shredded aluminum. This aluminum is then cast into a continuous ¾ inch thick sheet, immediately rolled to a 1/10 inch thick sheet, and finally into coil form. The coils then undergo cold rolling to achieve a final, predetermined thickness and go through various finishing processes, including tension leveling, e-cleaning, and coating. This ensures the aluminum sheet is perfectly tailored to the requirements of the end application.

This process demonstrates the significant role played by aluminum suppliers and flat rolled aluminum producers in transforming raw materials into usable aluminum. Aluminum producers then deliver the aluminum to various industries to manufacture many different products. This seamless collaboration results in the production and distribution of aluminum products we see and use every day.

The extraction and production processes for aluminum are undoubtedly complex. However, as we will explore in the following sections, it also presents significant sustainability challenges that the industry is striving to address.

The Importance and Implementation of Sustainability in Modern Aluminum Manufacturing

Sustainability in modern manufacturing is no longer an optional feature; it’s an absolute necessity. In the context of the aluminum industry, this implies the adoption of practices that minimize environmental harm, advocate social responsibility, and maintain economic viability.

But why exactly is sustainability crucial for the aluminum industry? Here are some key reasons:

- Environmental Impact Minimization: Given the highly energy-intensive nature of the aluminum industry, it significantly contributes to greenhouse gas emissions. By leveraging energy-efficient technologies, robust waste management initiatives, and extensive recycling, the industry can drastically decrease its carbon footprint.

- Addressing Social Concerns: The realm of sustainability includes worker safety, community engagement, and respect for indigenous rights. Acknowledging and addressing these elements results in a more ethical business model, a positive brand reputation, and a considerable competitive advantage.

- Economic Growth and Resilience: Investment in sustainability often results in cost reductions over time, thanks to efficient resource use and waste reduction. Moreover, as the demand for sustainable products escalates, new market opportunities emerge.

In essence, sustainability in the aluminum industry is a dynamic approach to addressing environmental challenges, encouraging social responsibility, and promoting economic growth.

The urgency of sustainable development has motivated the industry to innovate, with many manufacturers now making sustainability a core component of their operations.

Here are some of the sustainable practices and technologies currently being embraced in the sector:

- Increased Energy Efficiency: Numerous aluminum manufacturers are integrating energy-efficient technologies into their operations. These might include advanced smelting techniques or energy-efficient machinery, which can considerably diminish energy consumption and the associated emissions.

- Recycling and Waste Reduction: The recycling of aluminum is a pivotal sustainable practice in the industry. It not only decreases the demand for raw materials but also requires less energy compared to producing new aluminum. Additionally, many companies are exploring innovative methods to manage and reduce waste in their operations.

- Responsible Sourcing: More and more aluminum manufacturers are focusing on responsibly sourced raw materials. This means taking into account the social and environmental impacts of their sourcing practices and striving towards more responsible procurement strategies.

The benefits of these practices are substantial and far-reaching. They can significantly reduce emissions and waste from an environmental perspective. They can lead to cost savings and open up new market opportunities. Socially, they can contribute to the betterment of workers and communities.

Role and Responsibility of Aluminum Manufacturers and Suppliers

As the world grapples with the pressing need to embrace sustainability, aluminum manufacturers and suppliers have an essential role to play and bear significant responsibilities. Their actions can influence not only their immediate operations but also the broader industry and the global environment.

Here’s a glimpse of the roles and responsibilities these entities hold:

- Championing Sustainable Practices: Manufacturers and suppliers are tasked with leading the charge towards sustainability in the industry. This means investing in energy-efficient technologies, adopting waste reduction measures, and implementing sustainable sourcing practices.

- Responsible Sourcing: Procuring raw materials responsibly is a key obligation. This implies sourcing materials from regions that adhere to environmental regulations and respect workers’ rights, thus helping to mitigate the social and environmental impacts of mining.

- Promoting Recycling: Given that recycling aluminum saves approximately 95% of the energy required to produce new aluminum, manufacturers and suppliers must actively encourage and participate in recycling initiatives.

- Industry Collaboration: Sustainability is a shared goal, and it demands collaboration. Manufacturers and suppliers should work together with other stakeholders in the aluminum industry to share best practices, develop industry-wide standards, and collectively address sustainability challenges.

- Transparency and Accountability: Stakeholders, including consumers and regulators, increasingly demand transparency around sustainability efforts. Thus, manufacturers and suppliers must be open about their practices, take accountability for their impacts, and demonstrate progress in their sustainability journey.

By taking on these roles and responsibilities, aluminum manufacturers and suppliers can significantly contribute to a more sustainable future, not just for the industry, but for our planet as a whole.

Case Study: Golden Aluminum – A Beacon in Sustainable Practices

In the search for sustainability within the aluminum industry, we have made significant strides. Our innovative and environmentally conscious practices firmly establish us at the forefront of sustainability within the sector.

At Golden Aluminum, we don’t see sustainability as just a side note to our operations; it’s a core component of what we do. We recognize the immense value the Earth gives us, and we feel an innate responsibility to give back. This belief has led us to weave sustainability into the very fabric of our operations.

Here are a few key aspects of our commitment to sustainability:

- Energy-Efficient Technology: Our proprietary NexcastTM technology is a true game-changer, greatly reducing greenhouse gas emissions. As the most efficient method of producing aluminum globally, it utilizes 80% less energy compared to other mills around the world.

- Commitment to Recycling: Today, we’re proud to say that our production uses over 70% recycled aluminum as its raw material for many products. But we don’t stop there. Our sustainability efforts extend into other areas, like collaborating with shippers who are part of the EPA’s SmartWay Transport Partnership and recycling the pallets we use in our plant.

- Industry Recognition: Our commitment to sustainable, responsible production has not gone unnoticed. We’re a Performance Standard and Chain of Custody Standard certified member of the Aluminum Stewardship Initiative (ASI), a clear testament to our dedication to sustainable practices.

We’re proud that our contributions to environmental conservation complement our production of superior aluminum products.

Creating a Nurturing Work Environment

Our team is at the heart of everything we do at Golden Aluminum. Recognizing our people as our true strength, we’ve consciously fostered an environment that values, respects, and nurtures every individual. We’re committed to embracing diversity and creating an atmosphere where everyone can truly feel they belong. We realize that our success largely hinges on our employees’ contributions, and we’re determined to provide opportunities that promote growth, innovation, and value for every team member.

In conclusion, we’ve been able to demonstrate that productivity and sustainability aren’t mutually exclusive – they can thrive together in the aluminum industry. Our success story emphasizes the immense potential and importance of sustainable practices in manufacturing, shedding light on the path forward for the rest of the industry.

Conclusion

The aluminum industry is at a crucial juncture where the need for sustainability is more significant than ever. From extraction to production and supply, each step in the life cycle of aluminum presents both challenges and opportunities to contribute to a more sustainable world.

While the hurdles are substantial, such as energy-intensive production, environmental degradation, and social concerns, the industry is making strides towards overcoming them. Innovations in energy efficiency, robust recycling programs, responsible sourcing, and transparency have started to reshape the industry’s landscape.

As we move forward, the collective effort of manufacturers, suppliers, and other industry stakeholders will be paramount. By embracing their roles and responsibilities, these key actors can drive the aluminum industry towards a sustainable future. In doing so, they will not only benefit their businesses and the industry at large, but also make a substantial contribution to the well-being of our planet and its inhabitants.

Through the lens of sustainability, the aluminum industry’s story is still being written, and every action taken today will shape the narrative of tomorrow. Therefore, it is essential for us to continue this journey of sustainable development, meeting challenges head-on, innovating, and adapting, all with an eye toward a more sustainable future for all.

Why Aluminum is a Sustainable and Green Metal: Exploring its Environmental Benefits

Today we’re talking about sustainability and one material that stands out as a green choice: aluminum.

Sustainability means meeting the needs of the present without compromising the ability of future generations to meet their own needs. Balancing environmental, economic, and social factors is essential to create a world that is healthy, prosperous, and sustainable for all.

In this post, we’ll explore why aluminum is such a sustainable material, including its many environmental benefits such as its lightweight and recyclable properties, energy-efficient production methods, and low toxicity.

So, whether you’re a manufacturer or consumer, there’s a lot to learn about aluminum. Let’s dive in and explore this amazing material together!

Navigate to Any Section with Ease:

- Environmental Benefits of Aluminum

- Importance of Using Recycled Aluminum

- Sustainable Practices in Aluminum Production

- Conclusion

Environmental Benefits of Aluminum

Aluminum is an eco-friendly metal with numerous benefits for the environment. Here are the key advantages of aluminum:

- Lightweight and recyclable: Aluminum’s light weight requires less energy for transportation, reducing greenhouse gas emissions. It is also 100% recyclable, which helps to cut down waste in landfills and preserve natural resources.

- Energy efficient production: Compared to other metals, aluminum requires less energy to produce. The manufacturing process can be powered by renewable sources such as hydropower.

- Durability and resistance to corrosion: Aluminum is long-lasting and can resist corrosion, reducing the need for replacements and the waste generated by them.

- Low toxicity: Aluminum is non-toxic and poses no harm to humans or the environment, making it a safe material for various applications, including food packaging.

- Versatility for a range of applications: Aluminum can be used in different industries for various purposes, including transportation, construction, and packaging. Its versatility allows for a more sustainable alternative to other materials that have a larger environmental impact.

Importance of Using Recycled Aluminum

The 100% recyclable property of aluminum means that it can be recycled infinitely without losing its quality or properties. This makes it an ideal material for sustainable manufacturing and production practices. By using recycled aluminum instead of virgin aluminum, we can reduce the environmental impact of aluminum production in several ways.

When aluminum products are discarded, they can take hundreds of years to decompose in landfills. By recycling aluminum, we can reduce the amount of waste that ends up in landfills and prevent the unnecessary accumulation of waste.

When we use recycled aluminum, we reduce the need for mining and extracting new aluminum from the earth’s crust. This reduces the environmental impact of aluminum production and conserves natural resources.

By choosing to use recycled aluminum in your products and manufacturing processes, you can also contribute to a more sustainable future and help reduce the environmental impact of your operations.

Sustainable Practices in Aluminum Production: A Case Study of Golden Aluminum

At Golden Aluminum, we are committed to implementing sustainable practices throughout our operations. As a US-based supplier of flat-rolled aluminum sheets and coils, we prioritize sustainability in various ways, such as:

- Using an energy-efficient continuous casting mini-mill process that uses significantly less energy than traditional aluminum manufacturing methods, reducing our carbon footprint.

- Placing a strong emphasis on the use of purchased scrap as a raw material in production, which reduces the amount of waste that ends up in landfills and conserves natural resources.

- Setting a sustainability goal of increasing the use of green raw materials, such as aluminum made from renewable energy sources, to reduce our carbon footprint and promote sustainable production practices.

- Implementing waste reduction practices, such as minimizing water usage and reducing greenhouse gas emissions, to benefit the environment and streamline our operations.

Overall, we prioritize sustainability throughout our operations, from energy-efficient production methods to the use of recycled materials and waste reduction practices.

Conclusion

In conclusion, aluminum is a sustainable metal that offers numerous environmental benefits, including its lightweight and recyclable properties, energy-efficient production, durability, low toxicity, and versatility. The importance of using recycled aluminum cannot be overstated, as it reduces waste in landfills and conserves natural resources.

As a case study of sustainable aluminum production, Golden Aluminum has demonstrated its commitment to sustainable practices through its use of energy-efficient production methods, the prioritization of purchased scrap, a sustainability goal of increasing the use of green raw material, and waste reduction practices.

At Golden Aluminum, we are proud to have achieved an average recycled content of 63.5% in our tab stock products in Q1 2023, and we believe that the use of recycled aluminum is crucial to creating a more sustainable future.

We encourage individuals and businesses to prioritize the use of sustainable aluminum in their operations to help reduce their environmental impact and contribute to a more sustainable world.

Building a Career in the Aluminum Industry: Tips and Strategies

The aluminum industry has been around for centuries, with aluminum being the most abundant metal in the earth’s crust. But did you know that this versatile metal is not just for soda cans and airplanes? It’s also used in renewable energy, construction, and even sports equipment. With aluminum being infinitely recyclable, strong, lightweight, and energy-efficient, it’s no surprise that the demand for skilled professionals in the aluminum industry is high and stable.

As the world population grows, urbanizes, and industrializes, the need for sustainable and lightweight materials continues to increase. But with so many options in the industry, how do you choose a career path that’s right for you?

Navigate to Any Section with Ease:

- Is Aluminum a Good Career Path?

- Career Paths in the Aluminum Industry

- Is Aluminum Sustainable?

- Golden Aluminum as an Employer

- Conclusion

Is Aluminum a Good Career Path?

Looking for an exciting and sustainable career path? Consider the aluminum industry! Aluminum is a valuable and renewable resource with many benefits.

Firstly, aluminum is a prime example of a circular economy. This is because aluminum is infinitely recyclable, making it a sustainable and eco-friendly choice for businesses and consumers.

In addition, the lightweight and energy-efficient properties of aluminum make it a popular choice in industries such as transportation and construction. As demand for sustainable materials increases, the role of aluminum in meeting that demand is also set to grow.

Finally, as the world shifts towards renewable energy and electric transportation, the demand for aluminum is expected to rise even further, creating a stable and growing industry with a high demand for skilled professionals.

Career Paths in the Aluminum Industry

The aluminum industry offers a range of career paths, including engineering, manufacturing, operations, and sales. Engineering roles involve designing and improving aluminum products and processes, while manufacturing roles involve actually producing those products. Operations roles focus on the management and coordination of manufacturing processes, and sales roles involve selling aluminum products to customers.

Some specific job titles in the industry include:

- Metallurgical engineer

- Process engineer

- Production manager

- Quality control specialist

- Sales representative

- Supply chain manager

The education and training requirements for different roles in the industry vary. Some entry-level positions, such as machine operators, may require only a high school diploma and on-the-job training. However, most positions in the industry require a bachelor’s degree in a relevant field, such as materials science, mechanical engineering, or industrial engineering. Some roles, such as metallurgical engineering, may require a master’s or doctoral degree.

Is Aluminum Sustainable?

The aluminum industry is making great strides towards sustainability and is a top choice for environmentally conscious individuals interested in reducing their carbon footprint.

One reason for this is that aluminum is an incredibly sustainable material. Its infinite recyclability means that nearly 75% of all aluminum ever produced is still in use today, and recycling aluminum uses only 5% of the energy required to create new aluminum.

Furthermore, aluminum’s lightweight and strong properties make it an excellent fit for the transportation industry. By using aluminum in cars and trucks, manufacturers can significantly reduce weight and improve fuel efficiency, thereby creating a more sustainable future.

As the world becomes more focused on sustainability, the demand for eco-friendly materials like aluminum is expected to grow. The aluminum industry is therefore a promising career path for those passionate about sustainability, with a constant focus on innovation and energy efficiency at the forefront of the industry.

Golden Aluminum as an Employer

Golden Aluminum has been a major employer in Ft. Lupton, Colorado since 1982. The company started with aluminum cans and has since expanded to include beverage products, food containers, and automotive parts. Golden Aluminum’s success can be attributed to its dedication to producing high-quality products and the hard work of its 180 employees.

The company’s dedication to producing high-quality products extends to its use of materials such as 5000 series aluminum, which is known for its strength, durability, and corrosion resistance. As one of the top aluminum manufacturers in the country, Golden Aluminum works with aluminum suppliers to source the highest quality materials for its products.

As a mini-mill, Golden Aluminum can easily adapt to small and custom orders. The company has invested heavily in creating safer machinery and recognizes the importance of its employees. In 2023, it provided an average 8% merit increase to its workers.

Golden Aluminum’s dedication to creating a positive work environment is reflected in the long-term tenure of its employees, with many having worked for the company for over five years and 27% for over a decade. According to Jose Madera, Golden Aluminum’s Caster & Hot Mill Superintendent and Safety Sponsor, “if you put in hard work, opportunities happen. Golden Aluminum has plenty of work, overtime opportunities, and has been a stable place to support my family for over 20 years.” Jose also appreciates the unique benefits the company offers, including the 2x2x3 schedule, quarterly profit-sharing program, and leadership’s receptiveness to employee feedback.

Conclusion

The aluminum industry is a stable and growing industry with a high demand for skilled professionals.

As a versatile and sustainable material, aluminum has a wide range of applications, from transportation to construction and packaging.

Golden Aluminum, an aluminum manufacturer located in Ft. Lupton, is a significant employer in the industry, providing high-quality products to customers in the food, beverage, and automotive sectors.

The company’s success is a testament to the dedication and loyalty of its employees and its commitment to continuous improvement and innovation.

With the growing demand for electric and fuel-efficient vehicles, Golden Aluminum is well-positioned to increase its market share in the aluminum industry. As the industry continues to evolve with new technologies and innovations, there will always be a need for skilled professionals to keep up with the latest trends and developments.