Nexcast®: Now Available To Select Partners

Now being available to select partners exploring next-generation continuous casting

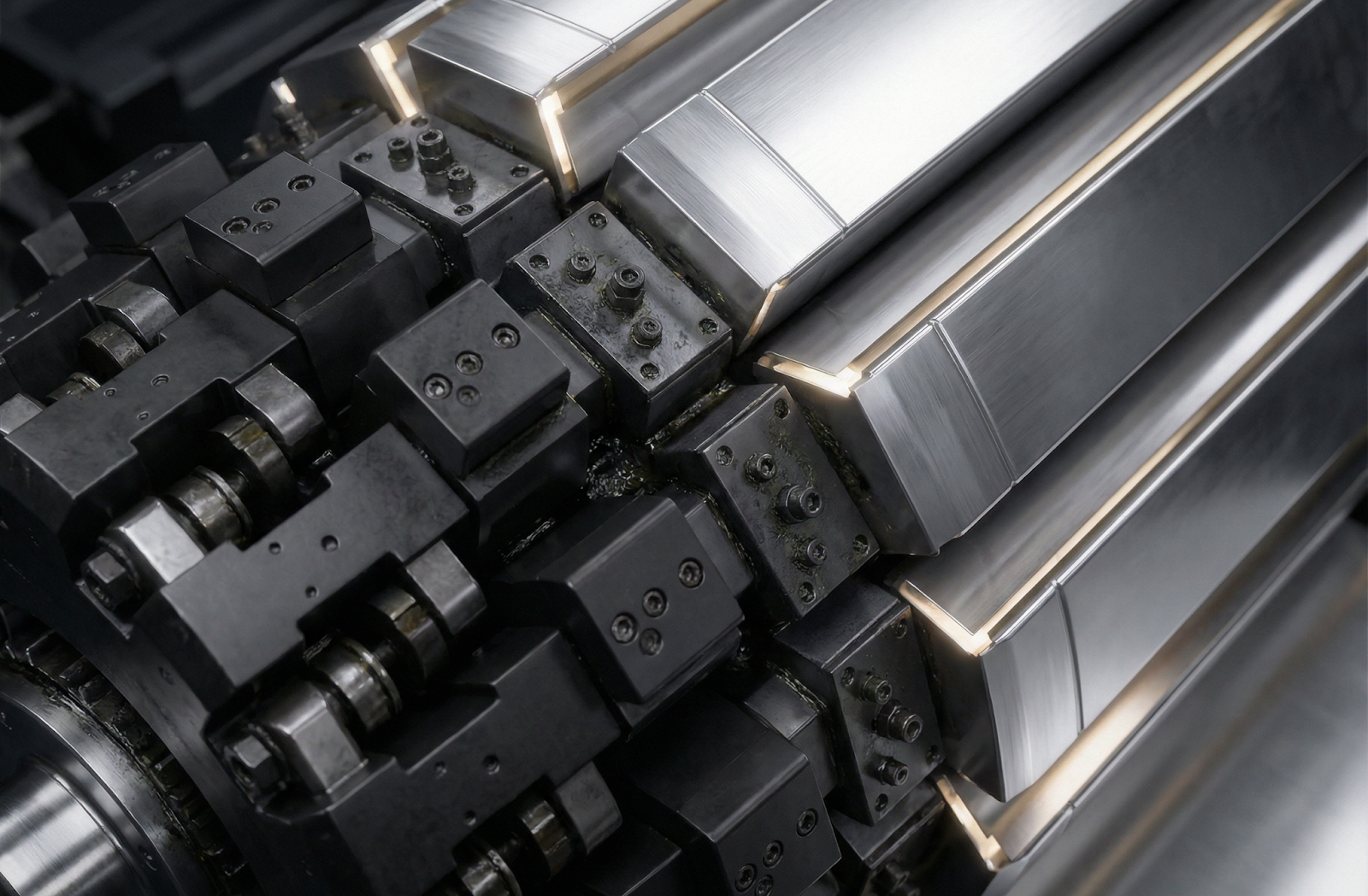

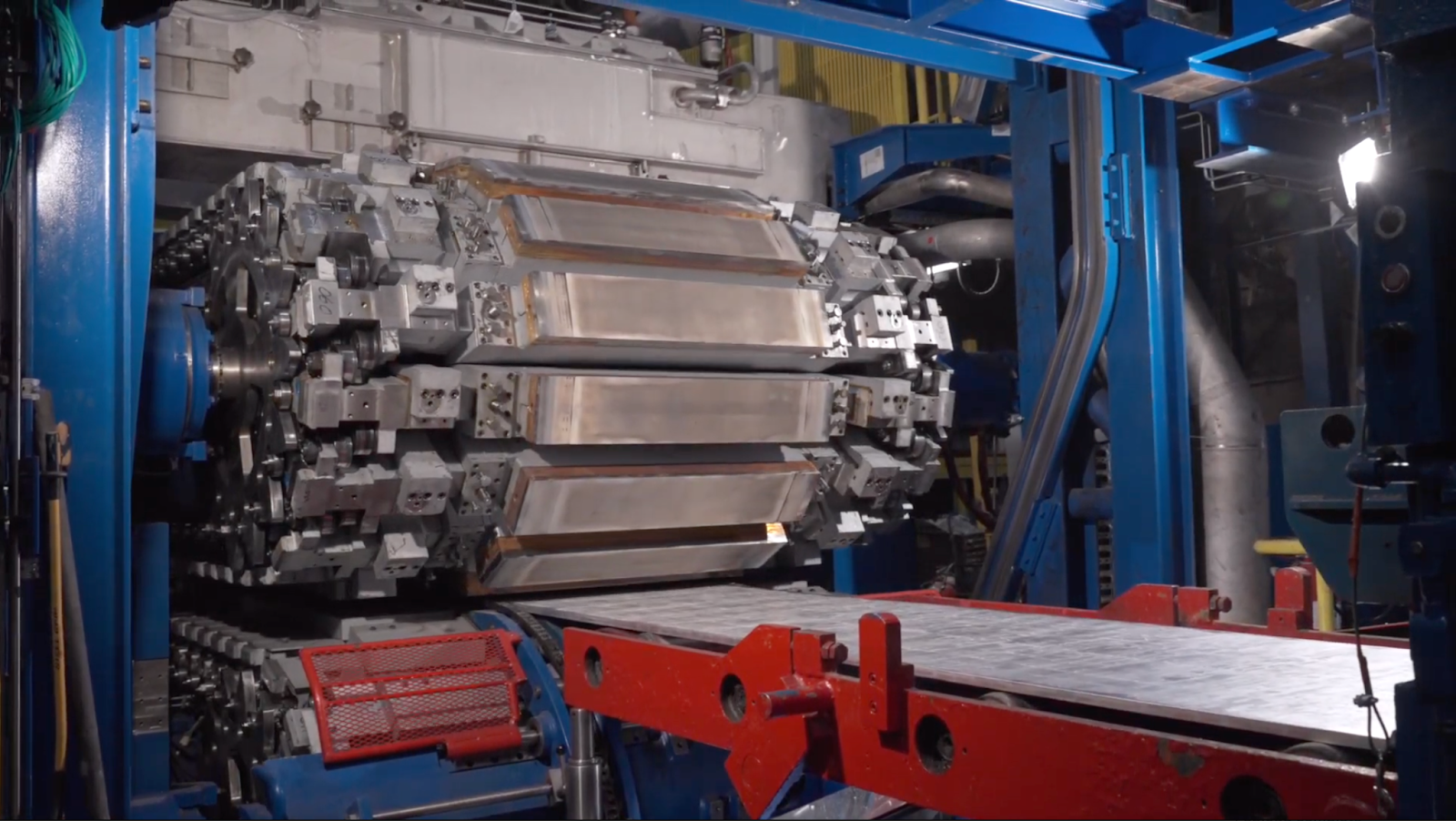

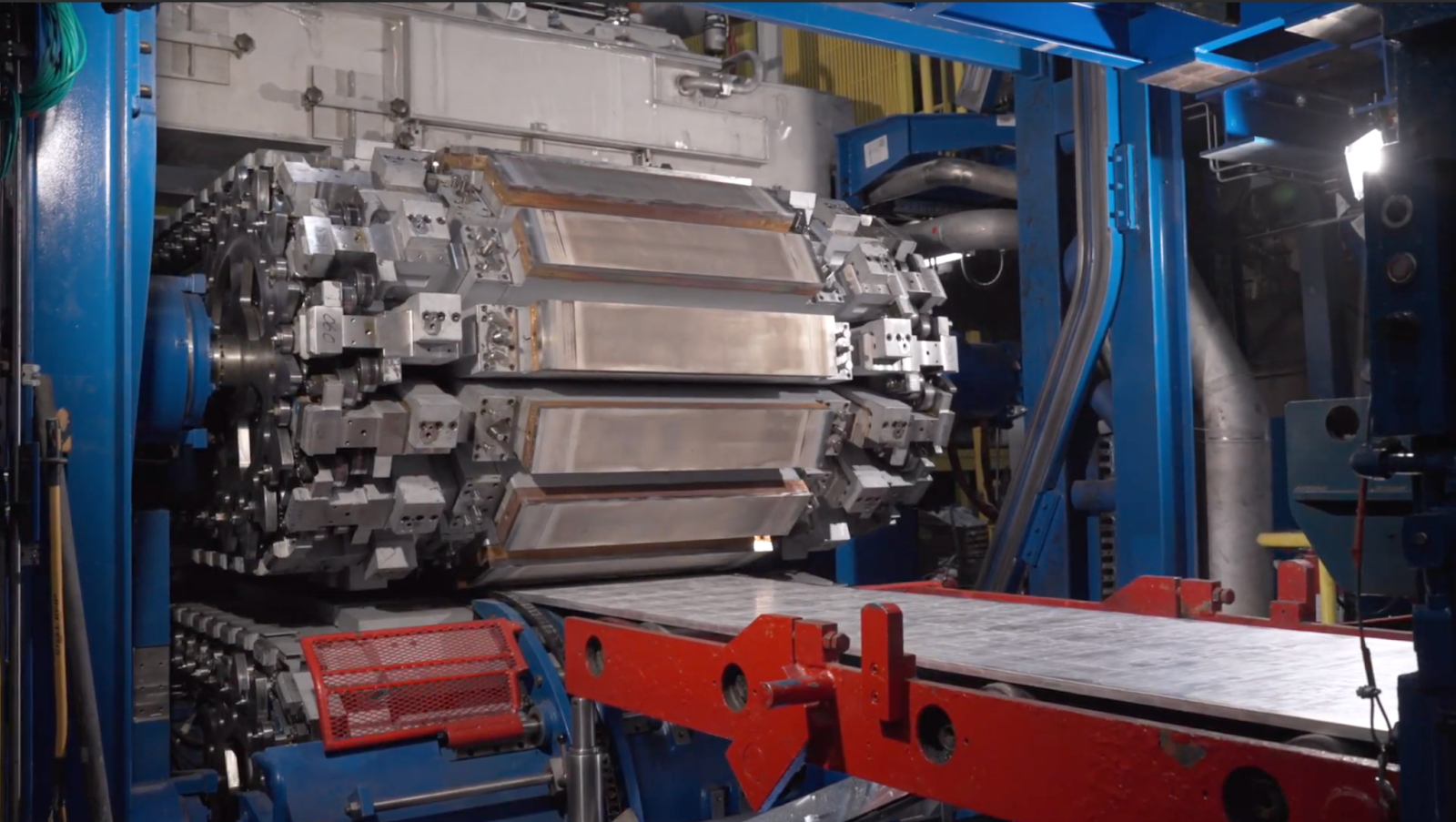

Co-developed with SMS group, Nexcast® is a breakthrough in continuous casting—now open to select partners exploring next-generation flat-rolled aluminum production.

For decades, Golden Aluminum has operated at the leading edge of continuous casting, building deep expertise in transforming molten aluminum into high-quality coil with speed, consistency, and efficiency. Nexcast® represents the next step forward: a modernized, optimized continuous casting system engineered to meet today’s demands for performance, sustainability, and operational flexibility—and built with the belief that progress shouldn’t stay siloed.

Why Nexcast® Matters

The aluminum industry is being asked to deliver more—greater efficiency, tighter consistency, and stronger energy and sustainability performance. Meeting that moment takes more than ambition. It takes better technology.

Nexcast® was developed to help meet those demands, with a design philosophy centered on:

- Modern engineering and control systems for stable, repeatable operation

- Efficiency gains that support lower energy intensity and smarter resource use

- Adaptability by design, enabling configurations tailored to different production requirements

Our Why

At Golden Aluminum, our mission is rooted in a simple belief: progress toward a more sustainable future accelerates when manufacturing breakthroughs can be accessed by others—anywhere in the world—especially when those breakthroughs happen here in the U.S.

That’s why we’re making Nexcast® available to select partners. Not as a departure from how we operate, but as an extension of what we believe: the industry moves forward when proven advances can spread.

Built to Fit Different Mill Needs

Every mill has its own constraints and requirements—product mix, throughput targets, facility footprint, and long-term growth plans. Nexcast® was built with that complexity in mind.

For organizations evaluating next-generation continuous casting, Nexcast® can be engineered to support different operating needs and configurations—through a collaborative approach led by Golden Aluminum and SMS group.

Learn More

For additional background and third-party coverage, read the article from Light Metal Age:

Golden Aluminum Advances Continuous Casting with Optimized Nexcast Blockcaster

Start a Conversation

If your organization is exploring next-generation continuous casting for flat-rolled aluminum production, we welcome the conversation.

New Year, New Plan: Choosing the Right Aluminum Partner for 2026

January is more than a fresh start on the calendar.

For manufacturers, it’s when the year truly begins — when forecasts are set in motion, sourcing plans start to execute, and long-term assumptions are tested against real demand and real expectations. It’s the moment when plans move from theory to action.

The aluminum market hasn’t stood still. Demand continues to grow, supply dynamics are evolving, and trade considerations remain part of everyday planning. In that context, the start of a new year often brings a simple but important question:

Is our current plan still the right one?

More often than not, that question leads back to one core decision — choosing the right aluminum partner.

Why a New Year Is the Right Time to Reevaluate

Many manufacturers operate on long-standing supplier relationships, and for good reason. Stability matters. But stability doesn’t mean standing still.

As markets shift, what once worked well can become less predictable. Capacity constraints, longer lead times, and changing cost structures can quietly introduce risk into even the most familiar supply chains. January offers a natural pause to step back and ask whether your aluminum strategy is still aligned with where your business is headed in 2026 and beyond.

This isn’t about reacting to disruption. It’s about planning deliberately.

What to Look for in a 2026 Aluminum Partner

A strong plan starts with clear priorities. As manufacturers look ahead, three considerations are increasingly shaping how aluminum partners are evaluated.

1. Reliable Capacity You Can Plan Around

At the foundation of any sourcing strategy is the ability to count on production.

Reliable capacity isn’t just about how much metal a supplier can produce in theory. It’s about consistency, predictability, and confidence that throughput will be there when demand rises. Partners with modernized equipment and fewer operational constraints are better positioned to support growth without unexpected bottlenecks.

For planners, this translates into fewer surprises and more confidence when committing to schedules, customers, and contracts.

2. Domestic Supply That Adds Stability

Location has always mattered, but it carries even more weight when trade dynamics and logistics timelines are in flux.

Domestic aluminum supply offers manufacturers a level of stability that’s difficult to replicate elsewhere — shorter lead times, closer collaboration, and fewer external variables influencing availability. As companies plan for 2026, many are placing renewed value on partners whose operations are firmly rooted in the U.S. and built for long-term continuity.

Domestic supply isn’t just about geography; it’s about resilience.

3. Smarter Energy and Scrap Use

Sustainability has moved beyond aspiration and into operations.

Manufacturers are increasingly looking for partners who can support both performance and environmental goals at the same time. Higher scrap utilization and more energy-efficient processes aren’t just good for reporting — they often lead to better material efficiency and a lower overall footprint.

As expectations continue to rise, smarter material choices are becoming part of what defines a strong aluminum strategy.

Turning a New Plan Into a Stronger Foundation

A new year doesn’t require reinventing everything. But it does invite a closer look at the foundations your plans are built on.

The right aluminum partner should reduce risk, support growth, and evolve alongside your business. That means capacity you can count on, supply that’s close to home, and processes designed with the future in mind.

When those elements are in place, planning becomes less reactive and more intentional — exactly where most manufacturers want to be heading into 2026.

Why Golden Aluminum Fits the Plan

At Golden Aluminum, these priorities shape how we invest, operate, and plan for the future.

With Nexcast® continuous casting technology, we’ve strengthened the fundamentals manufacturers care about most — capacity, reliability, domestic supply, and sustainability.

Just as important, we pair that technology with a team focused on understanding our customers’ needs and responding quickly when it matters.

Nexcast® was designed to support long-term planning by delivering:

- Reliable capacity through modern continuous casting, helping support consistent throughput and fewer production constraints

- Domestic flat-rolled aluminum production from our Fort Lupton, Colorado facility, offering stability and responsiveness close to home

- Smarter energy use and higher scrap incorporation, supporting both performance goals and sustainability targets

- Operational flexibility, including on-the-fly alloy changes that allow faster response to customer needs

Nexcast® isn’t just about keeping pace with demand. It’s about building a stronger foundation for the future of flat-rolled aluminum — supported by people who understand your business and work alongside you to keep plans on track.

If you’re revisiting your aluminum strategy as part of your 2026 planning, we’re always open to a conversation.

The right plan starts with the right partner.

How Aluminum Makes the Holiday Season Bright

You might not always notice it, but aluminum quietly powers some of our favorite holiday traditions: from the ornaments in your Christmas tree, to the glow in every decorative window display. Aluminum is everywhere this time of year.

At Golden Aluminum, we believe the season becomes even more special when everyday materials bring brightness, safety and sustainability into our homes and communities.

The Hidden Role of Aluminum in Holiday Cheer

Take a peek at any holiday display, and you’ll spot aluminum front and center. The glittering tree topper and stars? Lightweight and reflective. The twinkling tinsel and vibrant ribbons? That’s aluminum’s one-of-a-kind shine at work.

Designers love aluminum for its light weight and durability. Decorations can sparkle without weighing down branches or breaking easily. Plus, its natural corrosion resistance means aluminum keeps its brightness year after year, even when stored away during cold or damp seasons.

That kind of quality makes aluminum a quiet hero of the holidays—helping the magic of the season look its best and last for years to come.

Keeping the Season Bright, Efficiently

When the lights go up, aluminum gets to work behind the scenes. It’s one of the best materials for managing heat and reflecting light, which makes it essential for energy-efficient LED bulbs and fixtures.

The shiny surface behind your holiday lights helps them glow brighter while using less power. Aluminum reflects light evenly, reduces wasted energy, and keeps bulbs cool, all of which make your décor safer, longer lasting, and more sustainable.

At Golden Aluminum, we take that same mindset into our manufacturing process. Our continuous-casting technology uses less energy than traditional production methods, reduces scrap waste, and allows us to recycle aluminum directly back into our process. By designing efficiency into every step, we’re helping ensure that the materials used to light up the season are made with the same care for energy conservation that they promote.

Aluminum in Packaging: Where Beauty Meets Sustainability

Gift-giving is easily one of the best parts of the holiday season. The hidden star at work? Aluminum. From shiny foils and metallic wraps, to the protective packaging that keeps special deliveries safe, aluminum blends both beauty and functionality to keep the magic of the season alive.

Its reflective finish adds that festive touch we all love, but beyond aluminum’s good looks, it remains one of the most reliable packaging materials. It’s lightweight, durable, and fully recyclable—helping reduce the footprint of packaging that often peaks during the holidays.

Recycling the Magic: Aluminum’s Infinite Life

Even after the holidays wind down, aluminum keeps on giving: every piece of foil, every can, every sheet can be recycled endlessly without losing strength or shine. The same aluminum that helped light up your home this year could come back as something completely new next season.

That’s the magic of true circularity. And at Golden Aluminum, sustainability is a core part of our process. Our advanced systems allow us to melt down and reuse aluminum efficiently, reducing emissions and conserving resources. Each coil we produce helps close the loop on the lifecycle of aluminum, proving that high performance and environmental responsibility can go hand in hand.

A Proudly American Material

We’re proud to manufacture aluminum that supports jobs, communities, and industries across the country right here in the U.S., at our Fort Lupton, Colorado mill. Our teams work year-round to deliver high-quality, sustainable aluminum used in products that are integral to our daily life—including the ones that make the holidays shine.

When you choose goods made from American-produced aluminum, you’re helping fuel innovation, efficiency, and environmental responsibility right here at home. It’s a win for our economy and for the planet.

Conclusion

From ornaments and lights to packaging and recycling, aluminum plays a part in nearly every corner of the holiday season. It makes decorations sparkle, keeps energy use down, protects gifts, and ensures the materials we rely on come full circle.

At Golden Aluminum, we’re proud to help make that happen—engineering materials that bring together performance, beauty, and environmental responsibility to make the holiday season shine brighter, year after year.

Why Flat Rolled Products Will Define the Next Decade of the North American Aluminum Industry

The North American aluminum industry is at a crossroads. Demand for flat rolled products (FRP) is set to nearly double by 2035¹, despite already facing a shortfall of more than 2 million tonnes annually. Growth in electric vehicles, beverage packaging, aerospace, and construction is accelerating the need for reliable supply, but production capacity is struggling to keep up the pace.

For manufacturers, the implications are significant. Limited access to FRP means higher costs, delayed innovation, and greater reliance on imports. With tariffs restricting imports and energy prices challenging domestic smelting, now’s the time for the industry to prioritize more efficient, sustainable, domestic source and resilient production methods.

In this article, we’ll look at what’s driving the FRP supply gap, why it matters for industries across North America, and how Golden Aluminum’s Nexcast® system is positioned to meet rising demand with efficient, sustainable production.

How the FRP Deficit Affects Key Industries

The FRP deficit poses major consequences for North America’s biggest industries. From consumer goods to advanced manufacturing, every sector will feel the strain.

- Automotive: As EVs become more common, an aluminum shortage could mean higher material costs and production slowdowns.

- Beverage packaging: Cans are among the most recycled products worldwide, yet supply constraints risk pushing brands toward less sustainable alternatives.

- Aerospace: Aircraft manufacturing requires advanced aluminum alloys with strict performance standards. Any disruption in access poses both economic and operational risks.

- Construction: Aluminum’s strength and recyclability make it vital to infrastructure and housing projects. With investment in construction on the rise, expanding domestic FRP capacity will help ensure steady progress and long-term growth across the sector.

These challenges highlight why expanding domestic FRP production is essential—not only to meet future demand, but also to ensure the resilience of North America’s key industries.

Market Growth and Rising Demand

The North American FRP market, valued at approximately USD 8.5 billion in 2024, is expected to nearly double to USD 17.1 billion by 2035. Globally, aluminum demand is predicted to grow by nearly 40% by 2030, adding over 33 million tonnes of new consumption², ⁶.

One of the major drivers is the shift toward lighter, more efficient vehicles. In 1980, the average white-goods or passenger vehicle might have used around 120 pounds of aluminum; by 2030, that number could rise toward 556 pounds per vehicle as automakers adopt more aluminum in EV bodies and components. That increase alone represents millions of tonnes more aluminum demand globally.

Meanwhile, US and Canadian production capacity–especially for flat rolled products in key alloys–is constrained. Scaling up will require investment, both in raw capacity and more efficient, agile production techniques.

What’s Driving the Supply Gap?

Several factors explain why supply is struggling to keep pace with demand:

- Trade Policy and Tariffs: In June 2025, Section 232 tariffs on imported aluminum doubled to 50% (excluding the UK)⁴, ⁵. These protections reduce access to foreign supply while increasing costs.

- Pandemic Disruptions: COVID-19 exposed weaknesses in global supply chains, from raw material sourcing to shipping logistics. Many of those challenges are still felt today.

- Energy Costs: Aluminum smelting is energy-intensive. In the US, high electricity prices make restarting or expanding smelters difficult, especially as competition for power grows with technology and data center demand.

The result is a structural imbalance: strong and growing demand with limited–and often unreliable–supply.

Why this Matters for Industry Leaders

A heavy reliance on imports leaves manufacturers exposed to tariff uncertainties, unpredictable shipping timelines, and geopolitical risks. The FRP deficit sends a clear signal: now is the time to expand domestic production capacity. Companies that invest early in sustainable, efficient technology will be best positioned to meet future demand while providing stability to customers and industries.

The Nexcast® Advantage at Golden Aluminum

Since 1982, we at Golden Aluminum have built our business on innovation and agility. This spirit of innovation led to the development of our Nexcast® continuous caster technology: a key player in shaping a smarter, faster, and more sustainable future for aluminum manufacturing.

Built on decades of proven, continuous casting expertise at Golden Aluminum, our Nexcast ® technology is engineered for versatility and high-performance manufacturing—and is well positioned to respond to this moment of rapid demand growth.

Unlike traditional processes, Nexcast® delivers:

- Diverse Alloy Capability: Nexcast® technology supports production of a wide variety of alloys.

- Energy Efficiency: The system uses less energy per tonne of output compared to traditional DC processes, aligning with industry goals for lower-carbon aluminum.

- Flexibility and Agility: Nexcast® allows for on-the-fly alloy changes and rapid response to customer needs, ensuring shorter lead times and reliable supply.

- Domestic Reliability: The first Nexcast® has been installed in our Fort Lupton, Colorado, Golden Aluminum mill—offering a secure, US-based supply chain that reduces reliance on imports.

Nexcast® technology isn’t just keeping pace with market demand. It’s helping set the standard for the future of flat rolled products.

Looking Ahead

The North American FRP deficit represents both a risk and an opportunity. For industries that rely on aluminum, the risk lies in constrained supply chains. For producers, the opportunity lies in meeting surging demand with efficient, sustainable, and domestic production.

Golden Aluminum is prepared for this future. Through our Nexcast® technology and commitment to efficiency, sustainability, and reliable domestic supply, we’re helping to close the supply gap while supporting growth in automotive, packaging, aerospace, and construction markets.

If you’re looking to understand more about how Nexcast® works, or explore how Golden Aluminum can be your partner in reliable FRP supply, we’d love to connect. Explore our website or reach out to our team today.

Sources

- https://www.marketresearchfuture.com/reports/north-america-aluminum-flat-rolled-products-market-47426

- https://www.weforum.org/stories/2023/11/aluminium-demand-how-to-make-it-sustainable/

- https://www.aluminum.org/auto-aluminum-growth-era-electrification

- https://www.whitehouse.gov/fact-sheets/2025/06/fact-sheet-president-donald-j-trump-increases-section-232-tariffs-on-steel-and-aluminum/

- https://www.whitecase.com/insight-alert/trump-administration-increases-steel-and-aluminum-section-232-tariffs-50-and-narrows

- https://international-aluminium.org/report-reveals-global-aluminium-demand-to-reach-new-highs-after-covid/

Golden Aluminum Celebrates Manufacturing Day 2025

On Friday, October 3rd, we opened the doors of our Fort Lupton, CO mill to celebrate Manufacturing Day 2025. Over 200 guests joined us for a day dedicated to community, innovation, and advancing sustainability across the industry.

Held every year on the first Friday in October, Manufacturing Day (MFG Day) shows future workers, parents, and community members what modern manufacturing is all about. This national event highlights the creativity, technology, and talent driving the next generation of American manufacturing.

This MFG Day was a special one for Golden Aluminum, marked by a major milestone in our operations and the strengthening of our manufacturing community.

Why Manufacturing Day Matters

MFG Day is part of a nationwide effort led by the National Association of Manufacturers, The Manufacturing Institute, MEP Centers, and other partners to recognize the impact and importance of manufacturing. The fourth industrial revolution is pushing our industry towards rapid change, and with it come advancements in technology, as well as new career opportunities.

From robotics specialists to technicians, bioengineers to machine operators, there are more career paths than ever before. MFG Day gives students, parents, and future workers a chance to see it firsthand, and imagine where they might fit in.

For us at Golden Aluminum, it’s also a chance to share what we’ve been working on. And this year, we had something big to celebrate.

Spotlight on Nexcast®: Our Biggest Tech Upgrade in 40+ Years

A major highlight of the event was the introduction of our newly upgraded Nexcast® casting system—marking the most significant improvement to our casting technology in over four decades.

This next-generation system is a direct reflection of Golden Aluminum’s long-standing commitment to efficiency, sustainability, and technological leadership in the aluminum industry.

Our state-of-the-art casting system has the power to:

- Reduce carbon intensity by up to 60% compared to conventional processes

- Use over 80% recycled end-of-life scrap

- Cut water usage by approximately 86% versus traditional casting routes

- Simplify production by eliminating several intermediate steps

This upgrade replaces Golden’s original block caster, which had been the foundation of our production process for decades. With Nexcast®, we gain tighter process control, improved coil consistency, and the ability to handle a wider range of alloys, including high magnesium 5xxx grades. The system also streamlines production by converting molten aluminum directly into coil form, reducing energy and water consumption in the process.

A Celebration of Progress, Technology, and People

While we were excited to show off our new Nexcast® technology, this year’s MFG Day was really about bringing people together. Throughout the event, attendees were invited to tour our Fort Lupton facility, meet the teams behind our products, and take part in a celebration that included a community cookout, New Zealand ice cream, and our popular employee Auto Show.

Another Milestone for Golden Aluminum

Manufacturing Day 2025 was a reaffirmation of our company’s direction and priorities, reflecting our ongoing investment in our operations, team, and technology.

It was a meaningful day spent with fellow local officials, educators, workforce partners, employees and their families. It brought our community into the heart of our operations and demonstrated the critical role we all play in advancing the future of manufacturing.

Looking Ahead

Golden Aluminum’s heritage is rooted in innovation, sustainability, and pride in U.S. manufacturing. The successful installation of the Nexcast® casting system strengthens our ability to produce responsibly, operate efficiently, and meet the evolving needs of our customers.

As we look to the future, we remain committed to driving progress—both within our community and the industry—and contributing to a resilient, sustainable future for manufacturing.

Thank you to everyone who joined us to celebrate this important milestone. Here’s to what’s next!

From Steel to Speed: How Aluminum Transformed the Automotive Industry Forever

Aluminum may not be the first thing you think of when you get in your car, but its impact on modern automotive design is impossible to ignore. Lighter than steel, yet remarkably strong, aluminum plays a critical role in improving fuel efficiency, extending EV range, and enhancing vehicle safety.

In this article, we’ll be exploring how aluminum evolved from a special material to a core component in automotive manufacturing—and how it’s meeting the demands of today’s drivers and manufacturers.

Why Reducing Vehicle Weight Matters

From the moment cars first hit the road, engineers have wrestled with the fact that every extra pound slows you down. A heavier vehicle needs more power to move, more energy to stop, and more fuel (or battery power) to keep going. Shedding weight enables faster acceleration, better handling, and improved efficiency.

But for much of the 20th century, weight reduction wasn’t the priority. Steel was strong, affordable, and easy to mass-produce. It became the foundation of American car manufacturing, while aluminum was reserved for special projects where performance outweighed cost.

From Steel Dominance to Aluminum’s First Breakthroughs

The 1908 Ford Model T set the tone for American automotive production. Its sturdy steel frame and body were built to last, and in an era of unpaved roads, that durability was a necessity. For decades, carmakers stuck with what worked, and steel reigned supreme.

In motorsports, though, aluminum was gaining popularity. Its lighter weight gave race cars an edge, shaving seconds off lap times. In the 1920s and 30s, select luxury and performance brands incorporated the use of aluminum panels to improve agility without compromising strength. After World War II, European manufacturers experimented more widely, but for mass-market American vehicles, steel was still the go-to.

The Turning Point for Aluminum

The oil crises of the 1970s changed everything. Suddenly, fuel efficiency became a selling point, and engineers started rethinking every pound in a vehicle’s design. Through the 1980s and 90s, advances in aluminum alloys brought better strength, corrosion resistance, and workability—making it a more viable alternative for large-scale production.

Decades later, in 2015, Ford released an aluminum-bodied F-150. This was a major turning point for the industry, and proved that aluminum could deliver the toughness truck owners demanded, while cutting hundreds of pounds from the curb weight. Plus, fuel economy and towing performance improved.

Electric vehicles have only accelerated aluminum’s rise. Battery packs are heavy, and every pound saved in the chassis or body range. Many major EV companies have made aluminum a core part of their designs from the start, using it to balance strength, efficiency, and safety.

Why Aluminum Works So Well in Cars

Aluminum’s growth in the auto industry isn’t just about being lighter—it’s about solving multiple design challenges at once:

Lightweight strength

Roughly one-third the density of steel, with alloys that can match it in structural integrity.

Crash safety

Deforms in controlled ways to absorb energy in a collision, protecting passengers.

Corrosion resistance

Naturally forms a protective oxide layer, resisting rust and weather damage.

Sustainability

Can be recycled indefinitely without losing its properties, reducing environmental impact.

This combination makes aluminum ideal for today’s vehicles, from high-performance sports cars to family SUVs and electric trucks.

Golden Aluminum’s Place in the Story

At Golden Aluminum, we’re proud to have been a part of aluminum’s evolution for over four decades. Our 5000-series alloys like 5182 and 5754 combine strength, corrosion resistance, and formability—qualities that automakers depend on for everything from body panels to structural parts.

Our innovative Nexcast® system also strengthens our role in the U.S. automotive supply chain by improving casting speed, consistency, and energy efficiency. It allows us to deliver the quality automakers expect while reducing the environmental footprint of production. And because we produce domestically, we can keep supply chains shorter and turnaround times faster—key advantages in an industry where innovation moves quickly.

Looking Ahead

Aluminum’s rise from racing’s secret weapon to a core material in mainstream vehicles shows how much the auto industry can change when technology, performance, and efficiency goals align. It’s no longer a question of whether aluminum belongs in cars. It’s about how far it can take us.

From lighter, stronger trucks to longer-range EVs, aluminum will continue to shape the road ahead—and Golden Aluminum is ready to help drive the next chapter.

For more information on Golden Aluminum’s automotive alloys, explore our Automotive Solutions.

How Aluminum Changed the Way We Drink

It’s easy to forget the aluminum cans we know and use today were once a radical innovation. Beverage containers went from being heavy, less portable, and difficult to open, to lightweight, extremely portable, and easy to crack open with your thumb—thanks to the invention of the aluminum can-end tab.

In this article, we’re looking back at how aluminum and the invention of the can-end tab forever changed the way we drink.

From Glass Bottles to Church Keys

For decades, beverages came in glass bottles, and while they offered a reliable seal and preserved flavor well, they weren’t exactly practical. Glass bottles are heavy, fragile, and not so easily portable.

Metal beverage cans later made their way to the mainstream in the 1930s, but these early cans were made of steel, and came with their own set of challenges.

Opening a steel can required a tool known as a “church key,” which punctured two holes: one to drink from, and one for airflow. It was messy, slow, and inconvenient. These cans were also prone to rust and added significant weight to shipments.

The Rise of Aluminum

When aluminum gained momentum in the late 1950s, it completely changed the game. Unlike steel, aluminum’s light weight, corrosion resistance, and recyclability made it the preferred material for beverage manufacturers.

Coors and Hawaii Brewing Company were among the first to test aluminum cans, introducing early versions that cut down on weight and eliminated rust.

Aluminum cans were easier to transport, chilled more quickly, and didn’t shatter like glass. And aluminum’s biggest advantage came just a few years later with the introduction of the pull tab.

The Pull-Tab Revolution

In 1962, Ermal Fraze invented the first removable pull tab after attending a picnic and forgetting his can opener. His design allowed drinkers to open a can with their fingers—no tools, no mess, and no fuss. It wasn’t long after Fraze’s invention that the pull tab had become standard in the US.

But like most new innovations, it came with its own issues. Detached pull tabs quickly became a litter problem, and presented a new, unpredictable safety hazard: children or pets would sometimes swallow them.

Enter: the stay-on tab—a cleaner, safer solution that keeps the tab attached to the can. This basic design was introduced in 1975, and remains in use today.

A Cultural Shift

As aluminum cans became more practical, they also grew in popularity. They fit neatly into coolers and cupholders, travel easily to concerts and sports venues, and offer a far more sustainable choice than plastic. Over time, premium beverage brands and craft breweries embraced the can for its convenience and environmental benefits.

The shift from bottles to cans wasn’t solely about packaging, though. It changed how and where people consumed drinks all over the world. The portability of aluminum made it easier to take our favorite beverages anywhere and everywhere, without worrying about broken glass.

Golden Aluminum’s Role

Most people don’t think twice about opening a can—but our can-maker partners, including some of the world’s most recognized beverage brands, certainly do. And so do we at Golden Aluminum.

Every aluminum can-end tab we produce reflects our commitment to quality, reliability, safety, and precision—from our partners all the way to the final consumer.

Each can-end tab is the result of careful engineering, designed to open smoothly, stay attached, and recycle easily. It’s a small piece of metal, but it plays a big role in making beverage cans better for consumers and the planet.

Brands that value both performance, sustainability and customizability depend on our materials to create beverage packaging that’s not only functional, but also helps shape a greener future.

Looking Ahead

Aluminum didn’t just change beverage containers. It shifted the culture around how we drink. The way we open and enjoy canned drinks today is the result of years of focused engineering and incremental progress—no church keys necessary.

From increasing the recycled content in cans, to developing even more efficient designs, innovation in aluminum packaging is ongoing. At Golden Aluminum, we remain committed to advancing that future by making products that are lighter, stronger, and more sustainable.

How Aluminum Became a Part of Being American

Every Fourth of July, we gather with family and friends to fire up the grill, crack open a cold drink, and watch the fireworks light up the night sky to celebrate what defines our nation: resilience, freedom, and pride.

But what many people may not realize is how present aluminum is—not just in moments of celebration, but in almost every part of our daily lives.

From the soda can in your hand, to the industries and innovations that fuel our economy, aluminum is deeply embedded in American life.

Let’s take a closer look at how much we rely on this resilient metal.

Aluminum: The Metal of Many American Traditions

Beyond holiday gatherings, aluminum plays a part in so many daily rituals without us even realizing it!

Picture your classic American summer, and you’ll find aluminum in almost every detail: the sleek travel trailer on a cross-country road trip, the foil wrapped around a fresh corn on the cob, your favorite ice cold canned beverage—even the fireworks on the Fourth of July rely on aluminum powder.

From backyard barbecues and scenic drives, to beach hangouts and outdoor adventures, aluminum is always there.

A Backbone of Industry and Innovation

Aluminum’s significance extends far beyond consumer moments. It’s an essential material that’s continued to help shape key American industries: packaging, automotive, and construction.

Packaging: Aluminum’s lightweight nature, durability, and infinite recyclability make it the gold standard for beverage cans and food packaging. It helps brands deliver products efficiently while reducing environmental impact. In fact, the average aluminum can contains more recycled material than many other packaging types, supporting the circular economy and local manufacturing jobs.

Automotive: Automakers rely on aluminum to craft lighter, more fuel-efficient vehicles. Whether it’s a durable pickup truck built for the open road, or the next cutting-edge electric car shaping the future of transportation, aluminum’s strength-to-weight ratio makes it essential for modern vehicle design. It contributes to better performance, greater range, and reduced emissions.

Construction: From bridges and buildings, to electrical wiring and solar panel frames, aluminum’s durability and corrosion resistance make it a vital material for American infrastructure. It helps ensure that the structures we depend on—both old and new—are built to last, while supporting the shift toward sustainable, energy-efficient construction.

Across these industries and more, aluminum remains a foundation of American innovation and progress.

Golden Aluminum: Proudly Made in the USA

At Golden Aluminum, we’re honored to contribute to aluminum’s enduring legacy. As a US-based aluminum manufacturer, we’re committed to producing high-quality products with an emphasis on sustainability, safety and efficiency.

Our aluminum sheet and coil products are made using up to 80% recycled content, supporting the circular economy and helping to reduce carbon impact. Plus, our proprietary Nexcast® continuous casting system allows us to deliver material quickly and responsibly, helping our partners in packaging, transportation, and beyond stay agile and competitive.

Every coil we produce supports American industries and ingenuity, and we’re proud to manufacture right here in Fort Lupton, Colorado. We’re committed to creating good manufacturing jobs, investing in American communities, and collaborating with customers across the country to build what’s next.

A Metal for Today and Tomorrow

On this July 4th, it’s worth pausing to appreciate how materials like aluminum quietly add to our lives and play a part in building the American dream.

We believe aluminum’s story is far from finished, and it’ll continue to spark innovation, support sustainability, and shape the experiences that bring us together.

Here’s to the traditions we share, the industries we build, and the future we create, together.

From all of us at Golden Aluminum, have a Happy Independence Day!

Nexcast is Getting a Major Upgrade

After 40 years of reliable performance, Golden Aluminum is proud to introduce the next evolution of our groundbreaking Nexcast technology. Kicking off June 2nd, 2025, this major Nexcast upgrade is our most significant leap yet–ushering in a smarter, faster, and more sustainable future for aluminum manufacturing.

Why Nexcast?

Nexcast changes the game. By transforming molten aluminum directly into a thin strip and then into a hot coil, Nexcast eliminates ingot casting, sawing, storage, scalping, reheating, and large-scale rolling equipment.

This streamlined process helps lower capital investment and equipment costs, cut emissions and water usage, and increase throughput and alloy versatility.

With Nexcast, we’re making the production of flat-rolled aluminum faster, more efficient, and better for the planet.

What’s New with Nexcast?

Our upgraded blockcaster technology, set to go live in July 2025, represents the biggest achievement in our casting system in over 40 years.

Built on decades of proven, continuous casting expertise at Golden Aluminum, our new Nexcast system is engineered for versatility and high-performance manufacturing. Designed for agility and space-efficiency, the entire system spans just 175 feet—bringing smarter, more compact casting to the heart of our operations.

The system also incorporates more than 80% end-of-life scrap into production, delivering significant sustainability benefits: ~60% reduction in carbon intensity, and ~86% decrease in process water usage.

This upgrade marks a key step in our long-term strategy, allowing us to increase production efficiency, enhance precision and consistency, and strengthen our competitive edge.

Designed for a Circular Economy

At the heart of Nexcast is our commitment to sustainability. We’re building systems that not only perform, but also help protect the planet.

The Nexcast system significantly reduces land use and minimizes the environmental impact of construction, while also cutting emissions across the entire value chain. It’s built to align with the needs of environmentally conscious industries, from electric vehicles and renewable energy, to sustainable construction and infrastructure.

The Future of Aluminum Manufacturing Starts Here

For over 40 years, Golden Aluminum has led the way in continuous casting, developing systems that are efficient, adaptable, and environmentally responsible.

Now, with our Nexcast upgrade, we’re taking everything we’ve learned and applying it to a smarter, more technologically advanced casting system—one that’s built to meet the demands of modern markets and future-focused industries.

Visit goldenaluminum.com to learn more about our innovative approach to responsible aluminum production.

Stay in the Know

Want to learn more about Nexcast and Golden Aluminum? Subscribe to our newsletter for exclusive updates and more.

The Key to a More Sustainable Summer: Aluminum

Summer is easily our favorite season for so many reasons: warmer weather, endless outdoor adventures, family vacations, and of course, a big backyard cookout. But it’s also a time when our energy use and waste can spike, often without us realizing it.

That’s where material choices matter.

If reducing waste and making more sustainable choices is your goal for summer 2025, aluminum is where it’s at. It’s lightweight, durable, and endlessly recyclable, making it one of the most effective materials for reducing environmental impact without changing the way we live.

From the can in your cooler to the coil in your HVAC system, we’re breaking down all the ways aluminum can help reduce waste and lower your carbon footprint while making this summer the best (and most sustainable) one yet.

Break Up With Plastic Bottles

Love a cool, crisp beverage on a hot day? Aluminum cans outperform plastic bottles all the way. They cool faster, protect the taste of your drinks, and are way easier to recycle.

And, unlike plastic, aluminum doesn’t lose its quality with each recycling cycle. In fact, nearly 75% of all aluminum ever produced is still in use today.

Plus, aluminum cans are lightweight and easy to pack in and out, whether you’re headed to the mountains or the beach.

Choosing cans over plastic is one of the easiest ways to reduce single-use waste this summer.

Lighter Weight. Lower Emissions.

Aluminum plays a key role in making vehicles lighter and more efficient. In cars, trucks, trailers, and RVs, aluminum components help reduce weight, which improves fuel efficiency and lowers greenhouse gas emissions.

For summer travel, this means longer trips, fewer stops, and more money saved at the pump. Plus, a smaller carbon footprint along the way. Talk about a win-win-win!

Cool the House, Not the Neighborhood

When the temperatures rise, your HVAC system works overtime to keep things comfortable, with aluminum doing the heavy lifting.

Most HVAC units use aluminum coils to transfer heat efficiently, making it easier and more efficient to regulate indoor temps. That translates to less energy use and lower utility bills in a season where cool air conditioning isn’t just essential–it’s crucial.

Smarter Grilling, Less Waste

Nothing says summer quite like a big backyard barbecue. And aluminum makes it easier, cleaner, and more efficient.

Foil, grill trays, and heat-resistant aluminum components help distribute heat evenly and reduce mess. These materials are widely recyclable and simple to use, helping to keep waste to a minimum after the meal is over.

And when cleaned and recycled properly, these products re-enter the aluminum cycle instead of ending up in a landfill–a small shift that contributes to a cleaner future over time.

Recycle the Golden Aluminum Way

The #1 thing we love about aluminum? It never wears out.

A recycled soda can could be back on the shelf within 60 days, or repurposed as a car part, a window frame, or another can. As one of the most recyclable materials on the planet, its ability to be reused indefinitely makes it a key material in building a sustainable future.

At Golden Aluminum, we specialize in producing aluminum that supports a circular economy. Our production process is designed to reduce waste, conserve energy, and deliver high-quality materials made with recycled content.

We don’t just manufacture aluminum. We make it smarter.

A Sustainable Summer Starts with Sustainable Materials

No matter what plans you have in store this season, there’s an easy way to make it more sustainable. And it starts with aluminum: a material that performs well, lasts longer, and can be reused again and again.

From road trips to backyard hangouts, aluminum is key to a cooler, cleaner, and more sustainable summer. And at Golden Aluminum, we’re proud to help make this possible by using recycled content, reducing waste, and helping our partners make smarter, greener choices that last.

Visit goldenaluminum.com to learn more about our commitment to responsible aluminum production.